Products

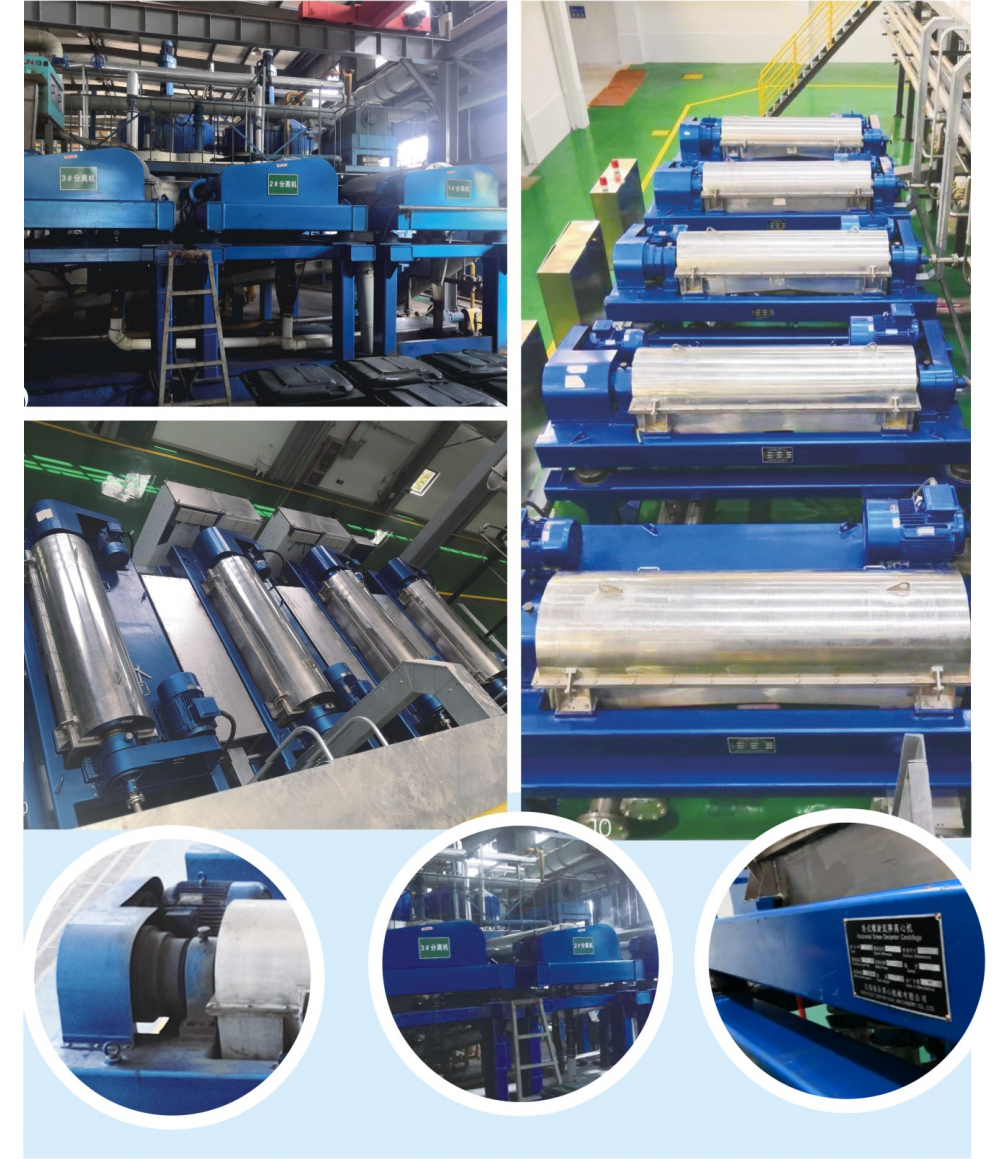

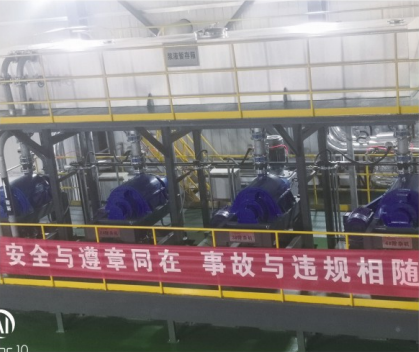

? Examples of customers separating kitchen waste

? Product description

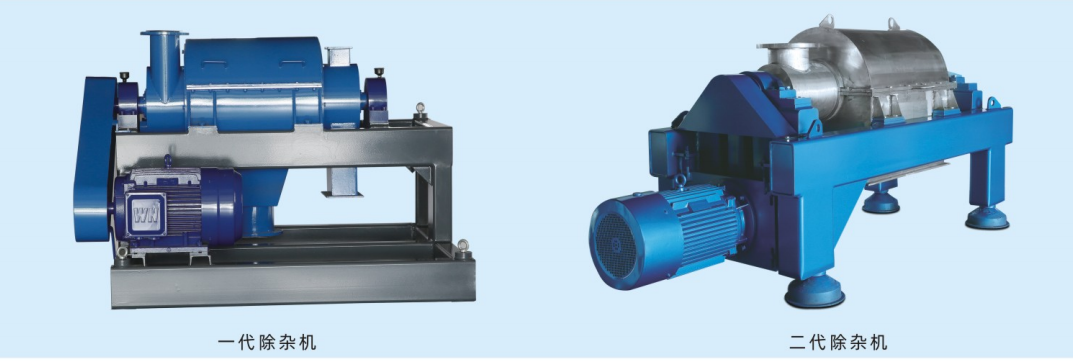

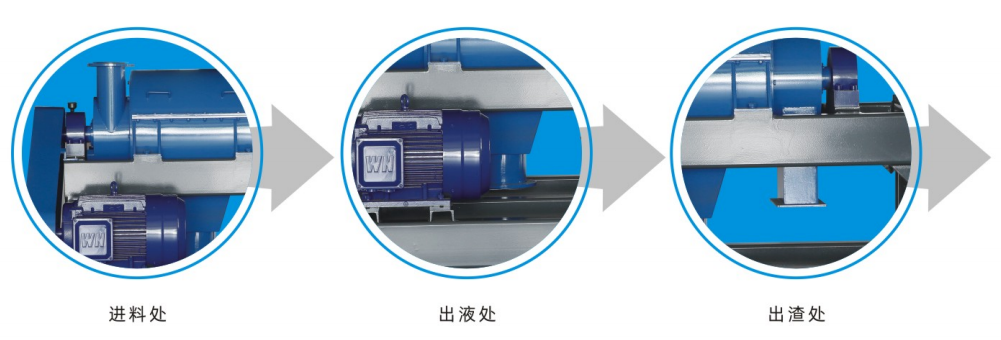

For the study of the previous process of centrifugal separation of kitchen waste and gutter oil,for the solid residue (plastic,fiber,shell,rag,etc.) in the material,the separation of the centrifuge and the wear of the spiral blade should be removed.Then enter the three-phase centrifuge separation,effectively ensure the separation effect of the three-phase centrifuge and reduce the failure of the three-phase centrifuge.There is a difference in the removal of impurities in kitchen waste and gutter oil.The impurity removal machine for processing kitchen waste is also called a sedimentation filter centrifuge.Its model is TXL series,which is divided into TXL300,TXL400 and TXL420 according to the processing capacity.

Disposal of kitchen waste is complicated and difficult to handle. Therefore, the sedimentation filter centrifuge is more suitable for processing. Simply speaking, it is a high-speed large-flow large-fiber slag removing machine, that is, it enters the sedimentation filter centrifuge after high-speed large-flow large-fiber large fibers The slag removal machine removes most of the large particles of solid slag and fibers, and then enters the two-phase horizontal spiral sedimentation centrifuge or three-phase horizontal spiral sedimentation centrifuge for separation.

? Features

The features of the sedimentation filtration centrifuge, also known as the high - speed, large - flow, large - fiber slag remover, are as follows:

A. It can remove 90% of large particles and a large amount of fibers. This greatly reduces the burden on the two - phase horizontal spiral sedimentation centrifuge or the three - phase horizontal spiral sedimentation centrifuge, minimizing the maintenance rate of these centrifuges.

B. The solid content of the slurry entering the sedimentation filtration centrifuge (i.e., the high - speed, large - flow, large - fiber slag remover) can reach about 15%. This significantly reduces the proportion of added water in the previous processes, lowers the operating cost, and reduces the generation of wastewater.

C. The removed solid slag is very dry with little water content.

D. Its processing capacity is quite large, reaching 8 - 20 tons per hour. This represents a breakthrough for industries such as kitchen waste treatment.

? Technical conditions

a. Equipment usage conditions

| Solid content in feed | ≤15% |

| Feed particle size | ≤8mm (Plastics and fibers can be ≤20mm) |

| Feed temperature | 30°C - 70°C (Depending on material properties) |

b. Technical specifications of TXL type sedimentation and filtration centrifuge

| Specifications and Models | TXL300 | TXL400 | TXL420 |

| Processing Capacity | 8-10 t/h | 10-15 t/h | 15-20 t/h |

| Solid Content in Liquid Phase After Separation | ≤ Mesh Gap | ||

| Moisture Content of Solid Residue After Separation | 60~70% | ||

C. Main configuration list of the equipment

| Name | Model TXL300 | Model TXL400 | Model TXL420 |

| Inner Diameter of Filter Screen | 300mm | 400mm | 420mm |

| Length of Filter Screen | 900mm | 900mm | 900mm |

| Gap of Filter Screen | 1 - 2mm | 2 - 2.5mm | 2 - 2.5mm |

| Screw Propeller | Three - bladed | Three - spiral - bladed | Three - spiral - bladed |

| Rotational Speed | 1500r/min | 1500r/min | 1500r/min |

| Separation Factor | 380 | 500 | 530 |

| Inverter | 37KW | 37KW | 37KW |

| Motor Power | 30KW, 4 - pole | 30KW, 4 - pole | 30KW, 4 - pole |

| Motor Model | Y200L-4 | Y200L-4 | Y200L-4 |

01. Centrifuge material: Both the filter screen and the screw propeller are made of 304 stainless steel and feature a forged welded structure. The pushing surface of the screw propeller blades is coated with a high - hardness and wear - resistant alloy material. The feeding pipe is made of 304 stainless steel, and all parts in contact with the material, such as the upper and lower casings, are made of 304 stainless steel. The bearing housing is made of ductile iron. The frame is made of welded section steel.

02. All bearings are SKF products.

03. The control cabinet has protection functions such as phase loss, overload, and over - current.

04. The sealing parts are all made of fluororubber.

SU ICP 05018101-1

SU ICP 05018101-1