Products

? STRUCTURE

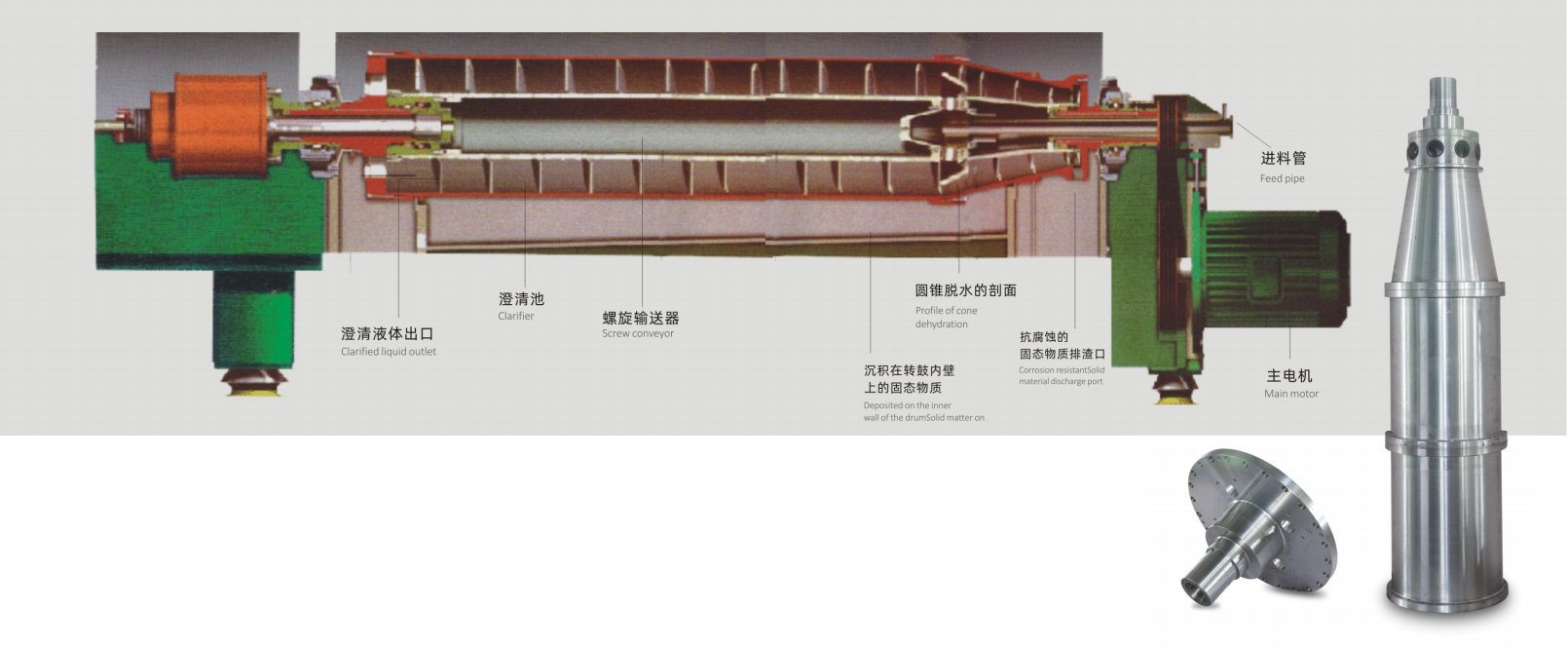

The LW horizontal screw centrifuge is composed of a conical cylindrical drum, a screw discharge device (hereinafter referred to as the screw), a differential system, a transmission system, a base and an electrical control system, etc. It is a mechanical equipment that uses the principle of centrifugal sedimentation to separate solid-liquid two-phase and liquid-liquid-solid three-phase suspensions of different specific gravities.

? WORKING PRINCIPLE

The drum of this machine is driven by the main motor.The frequency conversion motor and the gear box (or hydraulic motor)form the differential system between the drum and the spiral.The drum and the spiral rotate at the same axis at different speeds in the same direction.The feed pipe enters the drum through the spiral discharge port.Under the action of high-speed rotating centrifugal force,the solid particles with larger specific gravity settle to the inner wall of the drum.The solid particles are scraped off and pushed towards the small end of the drum and discharged from the slag discharge port.The liquid phase with a smaller specific gravity forms an inner liquid ring in the drum,which is continuously clarified along the spiral groove and flows to the big end of the drum.The overflow weir plate with adjustable caliber overflows,thus realizing the separation of solid-liquid two-phase or three-phase.The rotating speed of the drum,the differential speed between the drum and the spiral can be adjusted steplessly according to the characteristics of the separated material.

? LW DECANTER CENTRIFUGE FEATURES

It has a wide range of applicationsThe machine has a wide range of applications.The horizontal screw centrifuges of different models in our plant can be used for various technological processes such as concentration of suspension, solid-phase dehydration, liquid-phase clarification, three-phase separation, particle classification, etc. In the sludge treatment process, it can be used for sludge concentration,sludge dehydration and sludge concentration dehydration integrated treatment.

Corrosion-resistant

Machine material:corrosion resistance, wear resistance. High quality stainless steel or two-phase stainless steel is used for the parts of centrifuge drum, screw, feed pipe, shell and other parts in contact with materials.High temperature spraying w2c-65%super hard wear-resistant material or tungsmooth 70-rb super wear-resistant tubular welding wire is used for hardfacing protection of screw push material surface inlaid with super hard wear-resistant hard alloy block.

Automation

The machine control system has the functions of full-automatic operation, continuous monitoring, real-time feedback adjustment, fault alarm, data display, etc., so that the centrifuge is always in safe and optimal operation.

Strong adaptability

Strong adaptability to materials.Horizontal screw centrifuge can separate all kinds of suspensions with solid particle size ≥5u ~3mm, solid weight concentration≤30%, solid volume concentration≤70%, and solid-liquid specific gravity difference ≥0.05g/cm3. It has large processing capacity and low slag discharge water content.

Stability

The operation stability of the machine is good, the automation degree is high, and the operation site environment is good. The feed, separation and discharge of the centrifuge are carried out continuously under the high-speed and closed condition, and the differential speed or torque between the drum and the screw can be adjusted automatically according to the change of the solid-phase concentration of the feed, so as to prevent the blocking of the materials in the drum and ensure the stable operation and separation performance of the machine.The machine has compact structure, small floor area, convenient installation and maintenance, and clean production environment on the operation site.

? TYPICAL APPLICATION FIELDS

The liquid-liquid-solid three-phase separation processes are:

Food waste,food waste water-oil-solid particles,oilfield sludge,coal tar-water-solid particles,palm oil-water-solid particles.

| Solid-liquid Separation | Ammonium Adipate | Alum | Aluminum Hydroxide | Ammonium Bicarbonate | Ammonium Chloride | Ammonium Nitrate | Antibiotics | Barium Chloride |

| Ammonium Sulfite | Barium Carbonate | Strontium Carbonate | Calcium Carbonate | Calcium Hydroxide | Calcium Nitrate | Calcium Oxalate | Cellulose | |

| Barium Sulfate | Calcium Sulfate | Starch | Distiller's Grains Waste Liquid | PTA (Purified Terephthalic Acid) | Blood Meal | Soybean Protein | Brewer's Yeast | |

| Fermentation Broth | Electroplating Solution | Tartaric Acid | Sodium Sulfate | Polyvinyl Chloride (PVC) | Sind Powder | Desulfurized Gypsum | Purple Sweet Potato | |

|

Liquid-Liquid-Solid Three-Phase Separation |

Coal Tar | Palm Oil | Aged Oil from Oil Fields | Gluten Meal | Fish Oil | Oil Sludge | Animal Fat | Food Waste |

| Separation of two immiscible liquids with different specific gravities and solids | ||||||||

| Sludge Dewatering | Asbestos Sludge | Power Plant Sludge | Pharmaceutical Sludge | Steel Mill Sludge | Water Treatment Plant Sludge | PVC Sludge | Power Plant Fly Ash Sludge | Dairy Sludge |

| Oily Sludge | Manufacturing Sludge | Leather Sludge | Dyeing Sludge | Hydroxide Sludge | Alum Sludge | Natural Gas Desulfurization Sludge | Calcium Carbide Sludge | |

| Quartz Sludge | Automotive Sludge | Activated Sludge | Plaster Slurry | Paper Mill Sludge | Domestic Sludge | Fiberboard Sludge | Electroplating Sludge | |

| Oil Field Sludge | Anaerobic Sludge | Drilling Sludge | Soap-Making Sludge | Anaerobic Sludge | Wool-Washing Sludge | Biochemical Sludge | Mine Sludge | |

| Particle Size Classification | Zinc Oxide | Titanium Dioxide | Kaolin | Starch | Drilling Mud | Coal Flotation | Cryolite Flotation | Diatomite |

| Gypsum | Bauxite | Benzoic Acid | Ore | Silicon Carbide | Pigment Recovery | Porcelain Clay | Bauxite | |

| Liquid Phase Clarification | Soybean Protein | Peanut Protein | Fruit Juice | Beverage | Vegetable Oil | Citric Acid | Waste Oil Purification | Washing Water Purification |

| Clean Juice | Chlorine Dioxide Sludge | Benzoic Acid | Silicon Carbide | Benzene | Coconut Juice | Rapeseed Oil | Saponified Oil | |

| Industrial and Domestic Wastewater | Kaolin Wastewater | Dyeing Wastewater | Beer Wastewater | Rinsing Water | Deinking Rinsing Water | Zinc Oxide Wastewater | Domestic Wastewater | Refined Oil Wastewater |

| Starch Wastewater | Yeast Wastewater | Beverage Wastewater | Painting Wastewater | Manure Water | Electroplating Wastewater | Desulfurization Wastewater | Calcium Carbide Wastewater | |

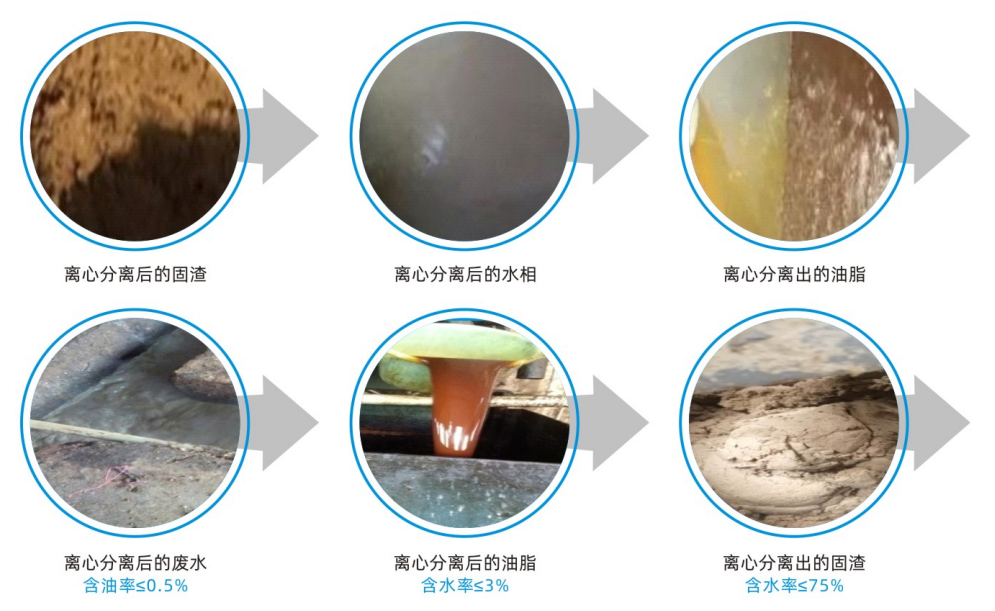

? Examples of food waste separation

? Three-phase fish oil treatment example

SU ICP 05018101-1

SU ICP 05018101-1