Products

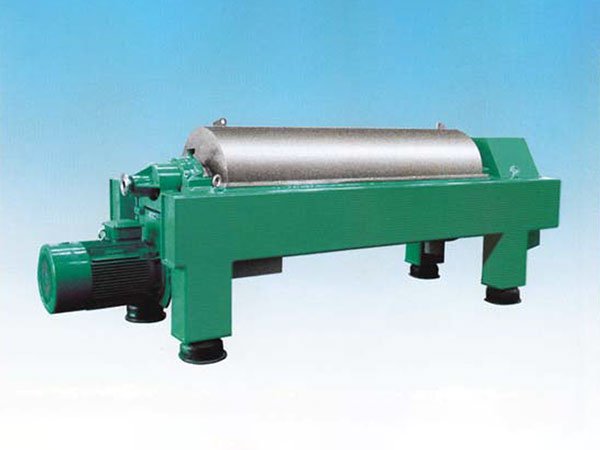

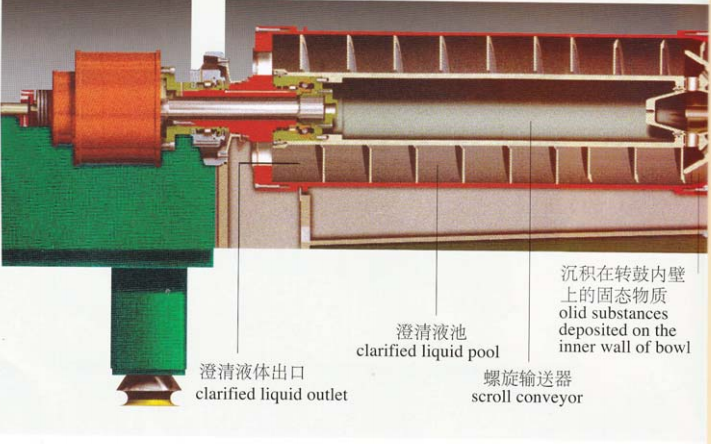

The LW horizontal screw centrifuge is composed of a conical cylindrical drum, a screw discharge device (hereinafter referred to as the screw), a differential system, a transmission system, a base and an electrical control system, etc. It is a mechanical equipment that uses the principle of centrifugal sedimentation to separate solid-liquid two-phase and liquid-liquid-solid three-phase suspensions of different specific gravities.

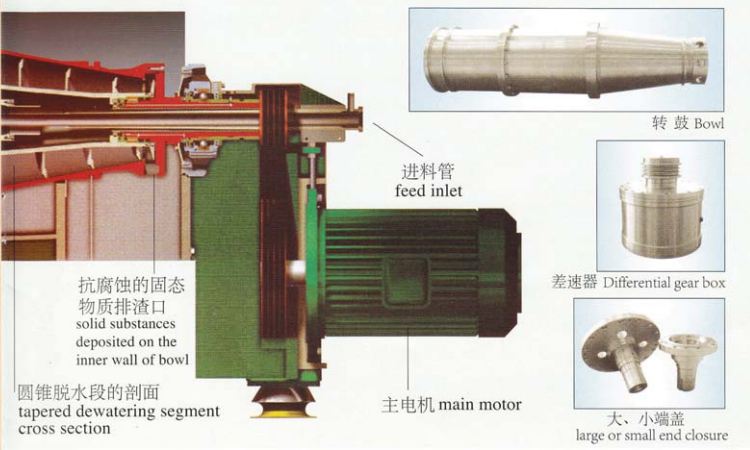

The drum of this machine is driven by the main motor, and the variable frequency auxiliary motor and the gearbox (or hydraulic motor) form a differential system between the drum and the screw. The drum and the screw rotate in the same direction at different speeds on the same axis. The suspension enters the drum through the fixed feeding pipe and the discharge port of the screw. Under the action of the centrifugal force of high-speed rotation, the solid particles with a larger specific gravity settle on the inner wall of the drum. Under the action of the spiral differential speed, the solid particles that have settled on the inner wall of the drum are continuously scraped off and pushed towards the small end of the drum, and discharged from the slag discharge port. The liquid phase with a lower specific gravity forms an inner liquid ring inside the drum and is continuously clarified along the spiral groove towards the large end of the drum, overflowing from the adjustable diameter overflow weir plate opening, thus achieving the separation of solid-liquid two-phase or three-phase. The rotational speed of the drum and the differential speed between the drum and the screw can be adjusted steplessly according to the characteristics of the separated materials.

1. The machine has good operational stability, a high degree of automation, and a good on-site operating environment. The feeding, separation and discharge of the centrifuge are carried out continuously under high-speed and sealed conditions. It can automatically adjust the differential speed or torque between the drum and the screw according to the changes in the solid phase concentration of the feed to prevent the material in the drum from clogging and ensure the stable operation and separation performance of the machine. The machine has a compact structure, occupies a small area, is easy to install and maintain, and the production environment at the operation site is clean and hygienic.

2. Strong adaptability to materials. The horizontal screw centrifuge can separate various suspensions with solid particle size ≥5u to 3mm, solid weight concentration ≤30%, solid volume concentration ≤70%, and solid-liquid specific gravity difference ≥0.05g/cm 3. The machine has a large processing capacity and low moisture content in the discharged residue.

3. The machine has a wide range of applications. Our factory's various models of horizontal screw centrifuges can be used in various process procedures such as suspension concentration, solid phase dehydration, liquid phase clarification, three-phase separation, and particle classification. In the sludge treatment process, it can be used for sludge concentration, sludge dewatering and integrated treatment of sludge concentration and dewatering.

4. Machine material: Corrosion-resistant and wear-resistant. The components of the centrifuge that come into contact with the materials, such as the drum, screw, feed pipe and casing, are all made of high-quality stainless steel or duplex stainless steel. The discharge port of the screw, the push surface of the screw and the slag discharge port of the drum are all protected by high-temperature spray W2C-65% super-hard wear-resistant material or Tungsmooth70-RB super-wear-resistant tubular welding wire.

5. The machine control and safety protection devices are complete and reliable. The machine control system features fully automatic operation, continuous monitoring, real-time feedback adjustment, fault alarm, data display and other functions, thus ensuring that the centrifuge always operates in an efficient state. The differential system can automatically feedback and adjust the pushing torque and differential speed according to the changes in solid load. The drum speed, the differential speed between the drum and the screw, the pushing torque of the screw, and the motor current can all be displayed. Measures such as gearbox torque protection, machine overload and vibration protection can effectively eliminate or reduce the damage to the machine caused by sudden accidents.

1. Those used in concentration, clarification and dehydration processes include: Polypropylene, polyethylene alcohol, polyvinyl chloride, mica, bleaching powder, calcium carbonate, calcium nitrate, silicon dioxide, aluminum hydroxide, lithium hydroxide, ferric hydroxide, potassium hydroxide, calcium hydroxide, aluminum oxide, ferric oxide, hydrouric acid, blue vitriol, chrome yellow, dye dispersant, pharmaceutical intermediate, nanomaterials, alum, Cinder powder, water-based foliar fertilizer, fermentation liquid, traditional Chinese medicine preparation. Starch, vegetable juice, monosodium glutamate, powder phthalein, brewer's yeast, soy milk, lactose, fruit juice, fish meal, mung bean products, distiller's grains, phospholipid powder, cellulose, lecithin, citric acid, soy protein, blood powder, beverages, peanut protein, vegetable oil, coconut juice, etc.2. Those used in particle classification processes include: Zinc oxide, titanium dioxide, kaolin, silicon carbide, diatomite, mica, drilling mud.

3. Those used in sludge concentration and dewatering processes include: Urban sewage treatment plant sludge, urban waterworks sludge, power plant ash, power plant sludge, petrochemical oily sludge, chemical sludge, coking sludge, oilfield sludge, steel plant sludge, pharmaceutical factory sludge, papermaking sludge, banknote printing sludge, printing sludge, soap-making sludge, dairy sludge, oil and grease sludge, alum sludge, acetylene sludge, tanning sludge, dyeing and printing sludge, slaughterhouse sludge, livestock and poultry sludge Coal slime, fermented liquid manure.

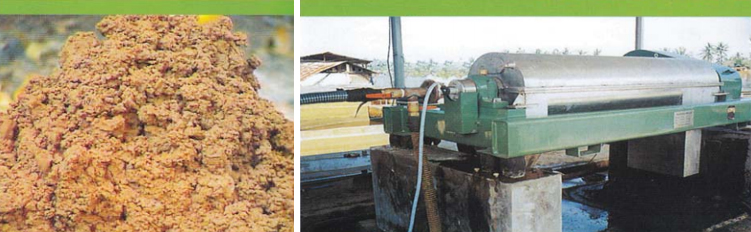

4. For liquid-solid: The three-phase separation processes include: coal tar - water - solid particles, palm oil - water - solid particles, and catering waste water - oil - solid particles.

SU ICP 05018101-1

SU ICP 05018101-1