Products

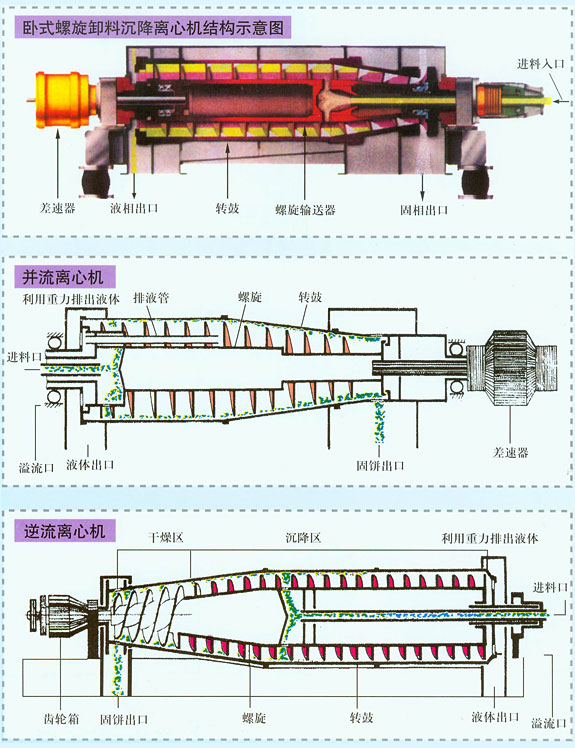

Horizontal screw decanter centrifuges are high-speed sedimentation centrifuges. They feature continuous operation, automatic discharge, compact structure, and high separation efficiency. With wide applications and reliable performance, they can meet the process requirements of clarification, dehydration, separation, and classification. Therefore, they are widely used in chemical, pharmaceutical, food, light industry, mining, petrochemical, environmental protection, and other sectors.

Horizontal screw centrifuges are machines that separate suspensions based on the sedimentation principle of centrifuges. They are suitable for various suspensions with solid particles sized between 0.005 - 3 mm, a weight concentration ratio of ≤ 10% or a volume concentration ratio of ≤ 70%, and a solid - liquid specific gravity difference of ≥ 0.05 g/cm3 for solid - liquid separation and particle classification. There are various types such as co - current, counter - current, and classification types.

Features

Continuous operation → Automatic discharge → Compact structure → High efficiency

Easy to maintain Small footprint

Our factory has developed six major series of horizontal screw decanter centrifuges, including LW - 220, LW - 350, LW - 400, LW - 450, LW - 530, and LW620, with a total of twenty - four specifications. The models include co - current, counter - current, and classification types. In terms of rotor structure, there are models for concentration, dewatering, classification, and clarification. The differential types include mechanical differentials and dual - frequency conversion + mechanical differentials. Therefore, they can meet the separation requirements of different users.

Product Selection

Our factory can also undertake the tasks of equipment selection, design, and manufacturing according to the special requirements of customers. To help users get the most suitable models, we recommend that users provide 500 ml of the material to be processed for small - sample tests, or provide more than 100 kg of materials for pilot tests on our factory's equipment. Our technical experts will determine the plan and select the models that satisfy users based on the experimental data and the technical indicators of the processing required by users and the materials to be processed. We welcome users to visit our factory for guidance. We will provide users with detailed technical consultation services and small - sample tests free of charge.

SU ICP 05018101-1

SU ICP 05018101-1