Products

This device is specifically designed for sludge concentration and dewatering of primary sludge, mixed sludge, chemical sludge, oxidation ditch sludge, and anaerobic and aerobic digested sludge in urban sewage and industrial wastewater treatment plants. It can also perform integrated concentration - dewatering and dewater the sedimentation sludge of urban waterworks.

? Features of the Complete Sludge Dewatering Device

1) It can work continuously and automatically for 24 hours.

2) For sludges with different physical properties, the centrifuge can be set to operate at different rotational speeds, differential speeds, and torques or in a constant differential speed state to ensure the clarity of the liquid phase, the dryness of the solid residue, and prevent material blockage inside the drum.

3) The flocculant dosing system can maintain a stable and continuous dosing concentration and dosage.

4) The entire device is a fully enclosed system. There is no splashing liquid or odor emission during the dewatering process, ensuring a clean operating environment.

5) The complete set of equipment is fully configured with a perfect automatic control system. It can operate safely after connecting the power supply and the material inlet and outlet pipelines.

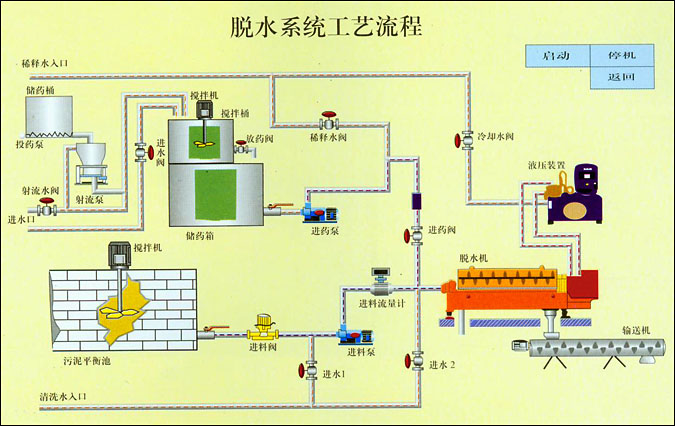

The complete sludge dewatering device consists of the following five major systems: sludge feeding system, flocculant dosing system, horizontal screw centrifuge, post - dewatering sludge and liquid conveying system, and electrical control system.

1. Sludge feeding system: It is composed of a sludge cutter, a sludge feeding pump, an electromagnetic flowmeter, valves, pipelines, etc.

2. Flocculant dosing system: It consists of a powder storage barrel, a powder metering device, a powder mixing/dissolving and ripening configuration tank, a flocculant storage tank, a flocculant metering pump, an electromagnetic flowmeter, a dilution device, pipelines, etc.

3. The horizontal screw centrifuges are available in dewatering type, concentration type, and integrated concentration - dewatering type. The differential speed systems of the centrifuges are configured as follows:

1) Mechanical differential speed system: The differential speed is adjusted by replacing the pulleys between the auxiliary motor and the gearbox, with an adjustment range of 3 - 45 r/min.

2) Electro - mechanical differential speed system: It is composed of a gearbox, an auxiliary motor, and an auxiliary frequency converter. The differential speed can be adjusted steplessly through the frequency converter, with an adjustment range of 3 - 45 r/min.

3) Hydraulic differential speed system: It consists of a hydraulic motor and a hydraulic station. The differential speed is adjusted by hydraulic pressure and hydraulic oil flow, with a relatively large adjustment range.

4. Post - dewatering sludge and liquid phase conveying system:

The post - dewatering sludge is conveyed by a shaftless screw conveyor made of stainless steel with an ABS engineering plastic lining. The conveying length is determined according to the user's requirements. It is recommended that the installation inclination of the shaftless screw conveyor should be ≤ 25°. The dewatered sludge can also be conveyed by a sludge screw pump or a belt conveyor. The liquid phase is sent to the next process for further treatment through pumps and pipelines.

5. Electrical control system: It has functions such as fully automatic operation, real - time feedback adjustment, fault alarm, and data display, enabling the centrifuge to always operate efficiently. The control system can start and stop the sludge cutter, sludge feeding pump, flocculant dosing system, horizontal screw centrifuge, and dewatered sludge screw conveyor in sequence or manually. It can set, regulate, and display the rotational speed, differential speed, and torque of the centrifuge, display the current and voltage of the main motor, accumulate the operating time of the main motor, and provide safety alarms for machine overload, vibration, and overheating of bearings.

? Working Principle

The sludge to be treated is connected to the input end of the sludge feeding system through a pipeline. The long - fiber impurities in it are cut and crushed by the sludge cutter, and then the sludge is metered by a flowmeter and input into the sludge dewatering machine (horizontal screw centrifuge) by a feeding pump (single - screw pump).

The flocculant (powder or liquid) is diluted in proportion and fully dissolved and stirred in the chemical preparation tank, then enters the chemical storage tank. Controlled by the dosing pump, it enters the dewatering machine at a flow rate determined by the dewatering process requirements. After being diluted to a concentration of 0.08 - 0.12% with dilution water, it is mixed with the sludge to be treated and flocculated into flocs. After the sludge is dewatered by the main dewatering machine, the clarified sewage is discharged through the clarified liquid pipeline, and the dewatered sludge is continuously discharged from the slag discharge port of the main machine. Then it is transferred to the designated location or directly loaded onto vehicles for outward transportation by a flexible shaftless sludge conveyor (or sludge residue transfer pump). The continuous input of the sludge to be treated, and the continuous discharge and transportation of the clarified liquid and dewatered sludge are a fully automatic treatment process. The dosing, feeding, sludge transportation, and the operating status of the main machine of the complete device are all detected and controlled by the fully automatic PLC electro - hydraulic control box, making the device a fully automatic complete operating unit.

SU ICP 05018101-1

SU ICP 05018101-1